Having a pharmaceutical label printing company that can meet your needs is important. You want to be sure you're getting quality work at a reasonable price. This can mean a variety of things. Some of the services you'll want to consider include: Laser marking systems, Thermal transfer overprinting, Lamination and varnishing, and Multi-layer labels.

Multi-Layer Labels

Choosing the right printer to produce your pharmaceutical labels is an important decision. You need a company that abides by strict industry standards and produces the highest quality labels. You need to consider the size of the text, the quality of the materials, and how the label will be used.

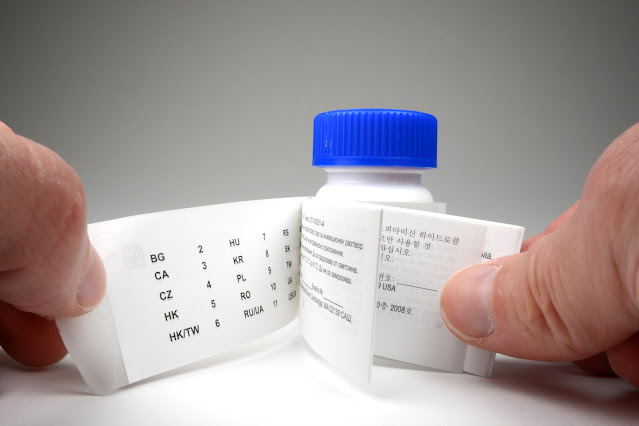

Multi-layer pharmaceutical label printing can be a valuable solution for your business. It is a cost-effective option for sticking your pharmaceutical products. These labels can include information such as ingredients lists, product names, and warnings. It also can incorporate special features.

In addition to sticking pharmaceuticals, these labels are ideal for other applications. They can be used to mark variable information, such as the date of production, batch numbers, or the location of the ingredients. These tags can also help combat counterfeiting.

Film

Using films for pharmaceutical label printing is an emerging trend. Film is a strong, flexible and durable material, making it an ideal choice for containers that will be subject to squeezing, tearing, or exposure to harsh weather conditions.

There are many different types of film materials. Some of them are designed to resist water, oil and chemicals. Others are weatherproof. There are also special inks that provide all kinds of effects. Film is typically more expensive than paper. The cost difference depends on several factors. The order size, the gauge, and the film material all play a role. However, most of these factors are not applicable to all film types.

The most important factor in determining the cost of a label is the order size. If the order is larger, the cost difference will be less. However, if the order is small, it may still be the case that film is more expensive than paper.

Thermal Transfer Overprinting

Choosing the right technology for printing on pharmaceutical labels can be challenging. There are many options available, including laser marking systems and thermal transfer overprinting. However, each technology needs to be tailored to the substrate and materials being used.

Laser marking uses a process that involves etching a surface layer of the substrate. Often, this process is used for blister marking, but it can take many different forms. Thermal transfer overprinting uses a system of transfer ribbons. The ribbon melts onto the label and forms an image. Thermal transfer overprinting is widely used in pharmaceutical packaging. This method produces high-definition marks and codes, and avoids the use of liquid ink. It can also print variable data.

In addition, it's an ideal printing technology for flexible packaging and industrial environments. This type of printing produces consistent, sharp prints. It's also a cost-effective solution for the flexible packaging industry.

Laser Marking Systems

Whether you're producing pharmaceutical label printing, food packaging, or electrical appliances, a laser marking system can help you meet traceability requirements and improve the quality and efficiency of your products. This technology is not only eco-friendly and cost-effective, but can also help you protect your products from counterfeiting.

The pharmaceutical industry is particularly susceptible to counterfeiting. Its impact has been enormous and has cost the industry over $16 billion. The proliferation of counterfeit products has opened the doors for organized crime, terrorism, and health risks. Using laser marking systems can help pharmaceutical companies prevent counterfeiting, and it can also help pharmaceutical manufacturers better supply pharmaceuticals to remote areas, improve the supply of small varieties, and reduce supply costs.

Traditionally, ink printing has been used to mark pharmaceutical labels. But ink-jet printing is prone to clogging and drying, spattering, and image distortion. Laser marking systems for pharmaceutical label printing on the other hand, are clean, non-contact, and can engrave images and text on packaging and containers without clogging or smearing.

Lamination and Varnishing

Whether you're printing labels for pharmaceutical products or other goods, there are many finishing processes that you can choose from. These include screen printing, embossing, and lamination and varnishing. These processes can help you produce a beautiful label that stands out on the shelf.

Lamination is a finishing process that involves applying a plastic film over the printed label. The film is waterproof and will provide your label with additional protection. You can choose between matte and gloss finishes. It's also possible to add a special varnish to your label for an extra effect.

Specialty varnishes are becoming increasingly popular. These varnishes can add unique effects to labels, such as embossing or high-rise varnishing. Some varnishes are also imprintable, which can be used to add variable information to the label.